Manufacturing of aluminium-bronze parts for energy, railways, valves, construction, marine , luxury....

Our Markets

The Aluminium-Bronze used in naval industry, rigging, offshore, petrochemical industry…

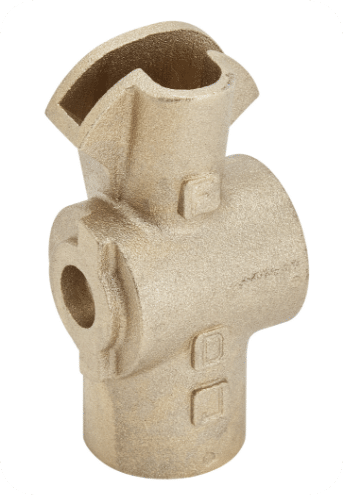

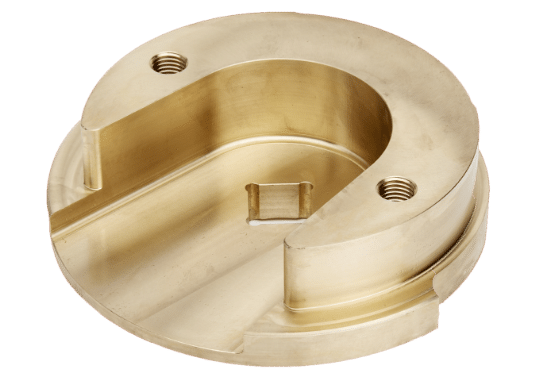

Aluminium-Bronze alloys are characterized by high resistance to various forms of marine corrosion, erosion, cavitation, stress corrosion cracking, and corrosion fatigue. They are indispensable in the production of mechanical components that must withstand corrosion or cavitation, such as butterfly valves, servo motor gears, and boat propellers. Cupro-Aluminium is used in firefighting equipment, water and sanitation markets, and in the manufacture of rigging components, leisure and sports boat equipment. Cupro-Aluminium also exhibits excellent performance in various chemical environments. The castability of Cupro-Aluminium allows for the production of components in diverse and varied shapes..

Uses of Aluminium-Bronze

The Aluminium-Bronze CuAl10Fe5Ni5 is extensively used in components of systems and installations designed to handle fluids, sometimes corrosive, such as seawater and certain chemicals.

It is employed in firefighting equipment, fittings, firefighter wrenches, irrigation systems, and ballast systems.

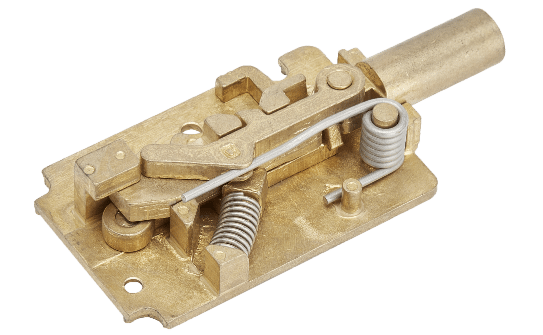

Locks, hardware, building components

Security for Your Installations

The exceptional castability of Aluminium-Bronze allows for the production of components in various shapes, diverse, and complex. Gravity casting in metal molds, tight and consistent dimensional tolerances reduce machining requirements. Aluminium-Bronze exhibits excellent corrosion resistance, thereby extending the lifespan of your components.

Advantages of Copper Alloy Parts

Aluminium-Bronze exhibits antimicrobial properties, reduces the risks of contamination, and is applicable to various frequently touched surfaces, such as door handles or cleanliness plates. Thanks to its outstanding properties in terms of wear resistance, Aluminium-Bronze significantly contributes to extending the lifespan of components and minimizing unforeseen maintenance downtime.

Railway, catenary technology and rolling stock

Manufacturing custom parts for the railway sector

Their electrical properties, high mechanical characteristics, not to mention their exceptional corrosion resistance, make CuAl10Fe2 Aluminium-Bronze alloys widely used on tramway up to High-Speed Trains catenary lines.

Foundry Davergne – contributor to the speed record of the French TGV (High-Speed Train)

Aluminium-Bronze exhibits excellent resistance to shocks, vibrations, wear, and matting. It is employed in the door mechanisms of metros and High-Speed Trains. Its favorable friction characteristics under high loads and temperatures enable Aluminium-Bronze to be used in various catenary components.

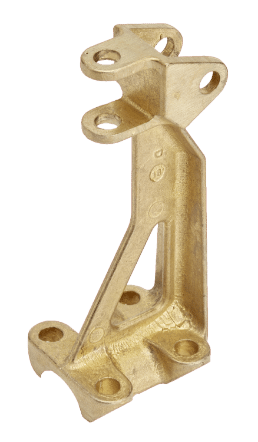

Mechanical industry and engineering

An alloy for the construction sector

Its strength, equivalent to semi-hard steel, combined with its good elasticity and high elongation, allows CuAl10Fe2 Aluminium-Bronze to be widely used in mechanical safety industries and the construction sector.

Parts for construction machinery

Withstanding high loads and exhibiting excellent long-term stability, Aluminium-Bronze can endure significant static forces. The alloy is used in high-tech equipment for infrastructure projects with substantial demands.

Boating

Bronze, like stainless steel, is extremely strong and corrosion-resistant. Turnbuckle cages made of Aluminium-Bronze significantly reduce the risk of thread seizing under high loads. A crucial feature for a more efficient and durable product. Our chrome-plated Aluminium-Bronze turnbuckles equip the rigging of sailboats that navigate the oceans. Another demonstration of the alloy’s resilience !

Aluminium-Bronze Parts for the Electricity and Energy Sector

Security Aluminium-Bronze CuAl10Fe2 for Electrical Components

The electrical characteristics combined with the high mechanical properties of Aluminium-Bronze CuAl10Fe2 make it a suitable material for electrical applications and connectivity. It is valuable in high-voltage substation connections, connection equipment for medium and low voltage networks, not to mention connectors in industrial and railway installations.

Grounding is an essential element for the quality and safety of your installations. The characteristics of Aluminium-Bronze meet specifications in grounding circuits, making this alloy an efficient means of current flow while avoiding the effects of lightning strikes.

Security and Compliance

High Performance

To withstand current-carrying constraints and prevent short circuits, Aluminium-Bronze must be securely fastened, and connections tightly secured. CuAl10Fe2 is perfectly suited for high-performance electrical applications in short-circuit protection systems.

Appearance parts and luxury components

A refined alloy for luxury components

Aluminium-Bronze is particularly well-suited for machining and allows for the attainment of super-finished surface states with precision tools. It exhibits excellent polishing capabilities. Various surface treatments such as copper plating, nickel plating, chrome plating, silver plating, and gold plating adhere perfectly and withstand the test of time.

High-end finishes

Aluminium-Bronze is commonly used for appearance components. Some non-exhaustive examples of applications include: the stirrups of the Republican Guard, components for culinary articles, hinges for luxury showcases and building entrances, decorative pieces for lampposts, and components for luxury luggage.

Aluminium-Bronze alloys are infinitely recyclable, without any alteration or loss of performance. This makes them a significant ecological asset across various industrial sectors.

Foundry

Cutting

Machining

Did you know ?

In New York, the Statue of Liberty was crafted by French artisans using over 80 tonnes of copper sourced from the copper mines of Visnes on the island of Karmøy, near Stavanger in Norway. Copper was a natural choice due to the long journey from France to America and its resistance to marine atmospheres. Since 1886, the statue, made of natural copper, has been protected from corrosion through the development of its distinctive green patina.