Our aluminium-BRONZE ALLOYS

Discover our alloys

In 1855, shortly after the discovery of aluminum, a bronze with the color of gold and the tenacity of steel was born: the Aluminium-Bronze.

Sainte Claire Deville and Debray were among the first to show interest, but it wasn’t until around 1900 that the systematic study of these alloys was initiated, a study that continues to this day.

Notable mention goes to Guillet, who in 1901 presented a study on these alloys to the Academy of Sciences. Also, the name Durville deserves recognition for inventing the tilt casting method around 1910, enabling the industrial development of these alloys, which has since continued to grow.

Remarkable Properties

Aluminium-bronze are copper-based alloys (80 to 90%) with aluminium content typically ranging from 8 to 10%. Simultaneous or separate additions of iron and nickel (1 to 5% each) are commonly made to enhance their mechanical properties and corrosion resistance.

Aluminium-bronze are characterized by high resistance to various forms of marine corrosion, erosion, cavitation, stress corrosion, corrosion fatigue, coupled with mechanical characteristics that, for certain compositions, are comparable to construction steels. These alloys also exhibit good performance in numerous chemical environments. The most common additions, such as iron or nickel, are primarily intended to increase mechanical properties. The exceptional castability of Aluminium-bronze allows the production of parts with complex and multiple shapes.

Our alloys

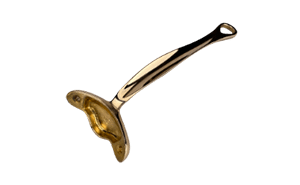

The CuAl9 Aluminium-Bronze alloys exhibit good polishability and are suitable for surface treatments such as nickel plating, chrome plating, silver plating, gold plating… This alloy is ideal for parts with a pleasing visual appearance.

Copper

Alloy : CuAl9

Exceptional flowability and good surface appearance…

The qualities of CuAl9 make it an essential alloy in applications where appearance is crucial.

Luxury and excellence trades have magnified this alloy by adapting it for their most prestigious creations. Our copper-aluminums are gravity casted in metal molds, and shell molding is suitable for medium and small repetitive series.

Copper alloys are infinitely recyclable without alteration or loss of performance, making them a significant asset in all industrial sectors. Resistance to atmospheric corrosion: copper-aluminum is naturally protected by a very stable copper oxide and alumina film that forms a superior protective film to any anti-corrosion coating. Copper alloys have antimicrobial properties, reducing the risk of contamination and applicable to numerous frequently touched surfaces such as door handles or cleanliness plates.

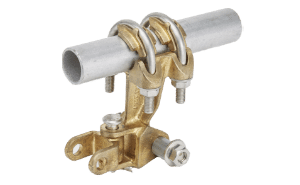

Aluminium-Bronze CuAl10Fe2 is an alloy recognized in various industries : railway, electrical, mechanical… It exhibits excellent long-term reliability.

Copper

Iron

Alloy : CuAl10Fe2

Equivalent strenght to a medium-hard steel coupled with good elasticity and a minimum elongation of 20%.

As an example and to demonstrate their exceptional characteristics, Aluminium-Bronze CuAl10Fe2 are used in seismic equipment. They exhibit good corrosion resistance and a beautiful gold color. These alloys are less susceptible than brass to stress corrosion in an ammonia-rich environment.

Common characteristics include: Rm = 600 MPa and A=20%. Aluminium-Bronze is also used in the construction sector to support high loads in aggressive environments. Applied in cutting-edge industries, Aluminium-Bronze CuAl10Fe2 is intended for railway equipment (catenary brackets), the chemical and cryogenic industry, mechanical and electrical industry, safety hardware, lock components, fire-resistant applications, armored doors, gate hinges…

The advantages of Aluminium-Bronze alloys: equivalent strength to medium-hard steel, good elasticity, high elongation, their structure remains unchanged under impact, excellent long-term stability.

The CuAl10Fe5Ni5 is resistant to atmospheric attacks and has excellent resistance to severe marine corrosion.

Copper

Iron

Alloy : CuAl10Fe5Ni5

An exceptional resistance to corrosion!

The CuAl10Fe5Ni5 is impervious to atmospheric attacks and exhibits excellent resistance to severe marine corrosion. This alloy demonstrates exceptional frictional properties under high loads and moderate speeds, along with excellent tensile strength and a high elastic limit.

Impact resistance: Subjected to impact work, Aluminium-Bronze is non-sparking. Not aging, it can endure very prolonged static efforts. Resistance to atmospheric corrosion: Aluminium-Bronze is naturally protected by a highly stable and high-melting copper oxide and alumina film, forming a protective layer superior to any anticorrosive coating applied to other materials. A high-strength alloy easy to polish, providing an alternative to brass due to the fineness of his grains. A chemical composition with very few impurities, especially lead-free.

Aluminium-Bronze falls into the category of high-security alloys, with no risk of stress corrosion cracking, ensuring that a part will not suddenly fail. This Aluminium-Bronze is suitable for marine applications (deck fittings, pumps, desalination units…).

Did you know ?

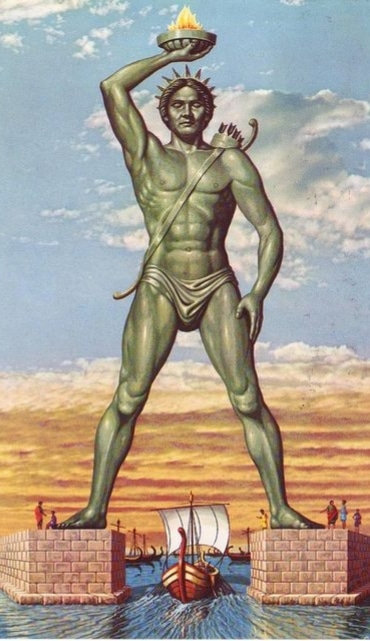

“The Colossus of Rhodes, one of the Seven Wonders of the World, was built in the 3rd century BC. It was made from bronze recovered from the weapons of conquered enemies. About 50 years later, the Colossus was destroyed by an earthquake, and the bronze was reclaimed and sold by the piece. This example shows us that the recycling of copper metals was already active in ancient times!”

Today, there is no trace left of this wonder of the ancient world. An ambitious project was envisioned by a team of young architects, archaeologists, engineers, and economists to reconstruct the Colossus of Rhodes in 2015. While nothing has been accomplished yet, the project captured the imagination of the internet.