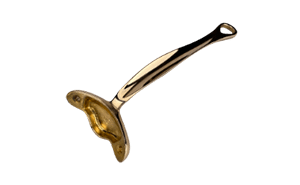

CuAl10Fe2

Our flagship alloy for universal use!

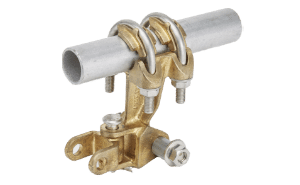

The addition of the element IRON enhances the mechanical properties to a high level, allowing CuAl10Fe2, known as Aluminum-Bronze, to be extensively used in the railway industry for over 70 years. Its undeniable qualities of robustness and reliability make it an essential alloy in all areas where stringent requirements are crucial. Due to its excellent mechanical characteristics, comparable to those of steels, coupled with its corrosion resistance and good conductivity, CuAl10Fe2 demonstrates outstanding long-term reliability and a complete absence of stress corrosion.

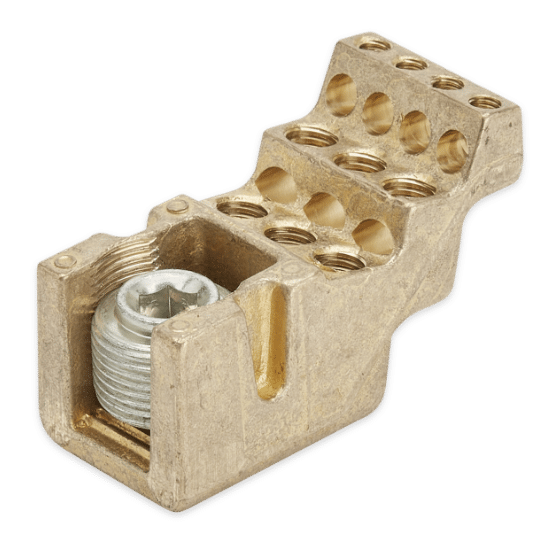

This alloy is gravity-cast into metal molds. The characteristics are improved through rapid cooling, thanks to the molds’ excellent conductivity. It is possible to overmold stainless steel inserts. Tight and consistent dimensional tolerances lead to reduced machining and a decrease in the weight of the parts.

Efficiency of Systems

The exceptional castability of Aluminum-Bronze allows for the development of new parts with complex shapes, ensuring reliability and system efficiency. CuAl10Fe2 exhibits a strength equivalent to medium-hard steel, exceptional resilience, a minimum elongation of 20%, without any alteration or loss of performance, making it a significant asset in various industrial sectors. Aluminum-Bronze get the ability to work under thermal constraints ranging from -250° to +300°, further enhancing its versatility.

Mechanical characteristics = CuAl10Fe2

Tensile strength = 600 MPa

Yield strength = 250 MPa

Elongation A = 20% minimum

Brinell hardness = 130 HB

Ideal for Railway Applications

For example, in the electrical domain: CuAl10Fe2 enables the use of smaller sections, saving space and consequently reducing costs while maintaining an equivalent current flow.

CuAl10Fe2

For example, in the electrical domain: CuAl10Fe2 enables the use of smaller sections, saving space and consequently reducing costs while maintaining an equivalent current flow.

Discover our other types of alloys.